By Romy Stephens

Two bright minds from the Dandenong Ranges are among over 100 Australian’s who have received the prestigious Churchill Fellowship.

The fellowship offers recipients a chance to work with leaders of influence around the world to gain knowledge and experience to help improve their industry and Australia.

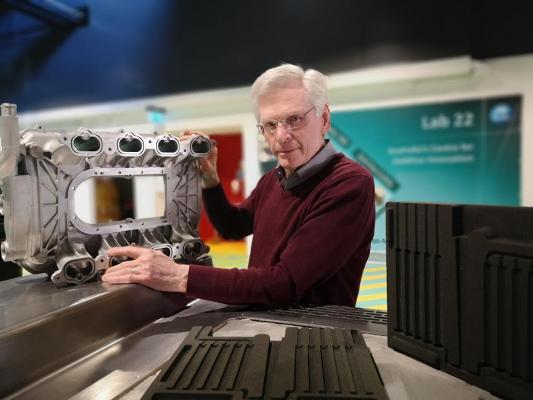

Emerald’s Gary Savage and Upwey’s Gavin Collis were local recipients this year. The pair are both research scientists at Australia’s national science agency, CSIRO.

Mr Savage’s fellowship will allow him to travel to Canada and the UK to gain practical experience from overseas foundries.

“A foundry is a place that melts metals and casts it into shapes,” Mr Savage said.

“My father owned a foundry…I grew up in that environment where I walked out the back door of the house and five metres away was the foundry.”

Despite initially wanting to steer clear of his father’s footsteps early on in his career, fate soon brought Mr Savage back into the metallurgy industry.

He landed his first job as a trainee metallurgist at BHP before progressing in his career and ending up at CSIRO, where he has been for over 25 years.

Mr Savage said he hoped to now leave a legacy within the industry before retiring.

Inspired by the works of one of the world’s leading experts in the casting industry, John Campbell, the Emerald local is preparing to use his fellowship to help improve Australia’s sovereign capability.

This refers to the country’s ability to design, maintain and develop assets without needing to import from overseas.

“You have to have supply chains to keep your own forces going, your air force, army and navy…You have to have a certain capability in your country to make certain critical things,” he said.

“Australia is not a cheap labour force country. We get paid a reasonable wage, we have a good standard of living. That means when you manufacture something it’s expensive compared to low-cost countries.

“A lot of foundries have closed over the decades and a lot of jobs have been lost to low-cost countries.

“Some of that work is starting to come back and I have a view that there’s still an opportunity for manufacturers in Australian foundries to make products that have technology embedded in them.”

Dr Collis’ fellowship will see him travel to America visit and work with some US national laboratories, like CSIRO, to develop a better understanding of battery materials and battery recycling.

“A lot of the work I do at the moment is around current and next generation lithium-ion batteries,” Dr Collis said.

“Most of the lithium-ion batteries used today are for consumer electronics but there’s been more growth in recent years.

“They’re starting to make and use electric vehicles that have lithium-ion batteries and also for energy storage.”

In Australia about 95 per cent of waste lithium-ion batteries end up in landfill.

Therefore, Dr Collis will be looking at how these batteries could instead contribute to a circular economy – an economy that reuses and recycles as much as possible.

Dr Collis said he will also explore how Australia can strengthen its battery manufacturing industry, with the country hosting an abundance of natural mineral wealth.

“We could actually start manufacturing battery materials and batteries in Australia and we’re now starting to find global companies that are wanting Australian resources to start making batteries,” he said.

“We essentially can create the entire value chain in Australia, there’s not many countries in the world that can do that.”

Despite Covid-19 putting international travel on hold, the Winston Churchill Trust has still awarded 112 fellowships.

Recipients will be granted an extended timeline to complete their fellowships due to the pandemic.

To find out more about the Churchill Fellowship, and other recipients, visit www.churchilltrust.com.au.